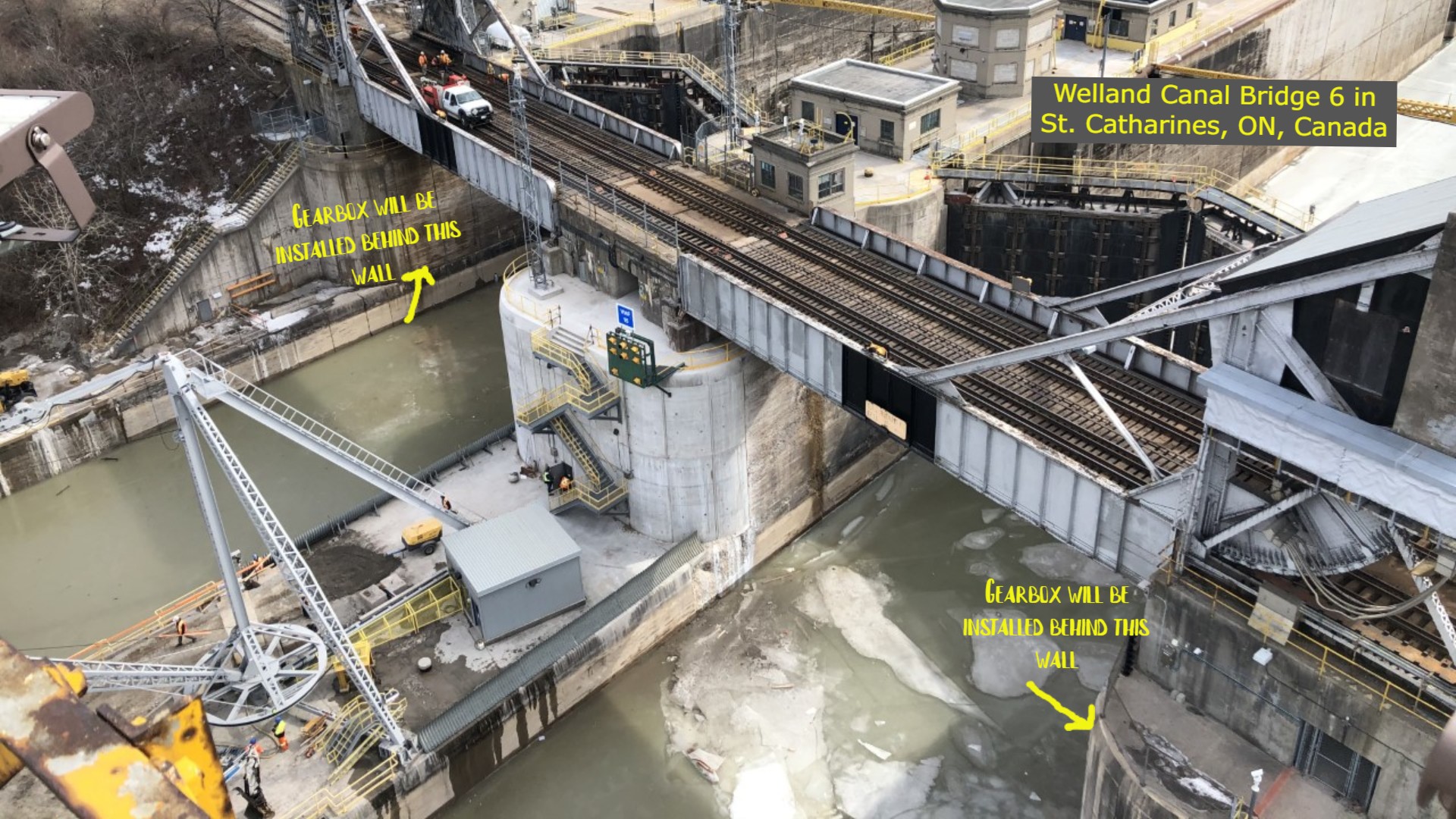

Our amazing team completed a huge project for The St. Lawrence Seaway Management Corporation! This 6 gearbox project (and test stand) is part of a major rehabilitation of Bridge 6 East and West at the Welland Canal, Niagara Region – Canada.

The Welland Canal is a ship canal in Ontario, Canada, connecting Lake Ontario and Lake Erie that enables ships to ascend and descend the Niagara Escarpment and bypass Niagara Falls. Approximately 3,000 ships pass through here each year along with 40,000,000 tons of cargo.

Each of the 2 bridge halves are raised and lowered with 3 gearboxes; 1 primary gearbox and 2 secondary gearboxes. The primary gearbox is driven by 2 electric motors–the output shaft of the primary gearbox drive the input shaft of each secondary gearbox, and the output shaft of each secondary gearbox drive a pinion on each side of the bridge of the rack and pinion system, which raises and lowers the bridge.

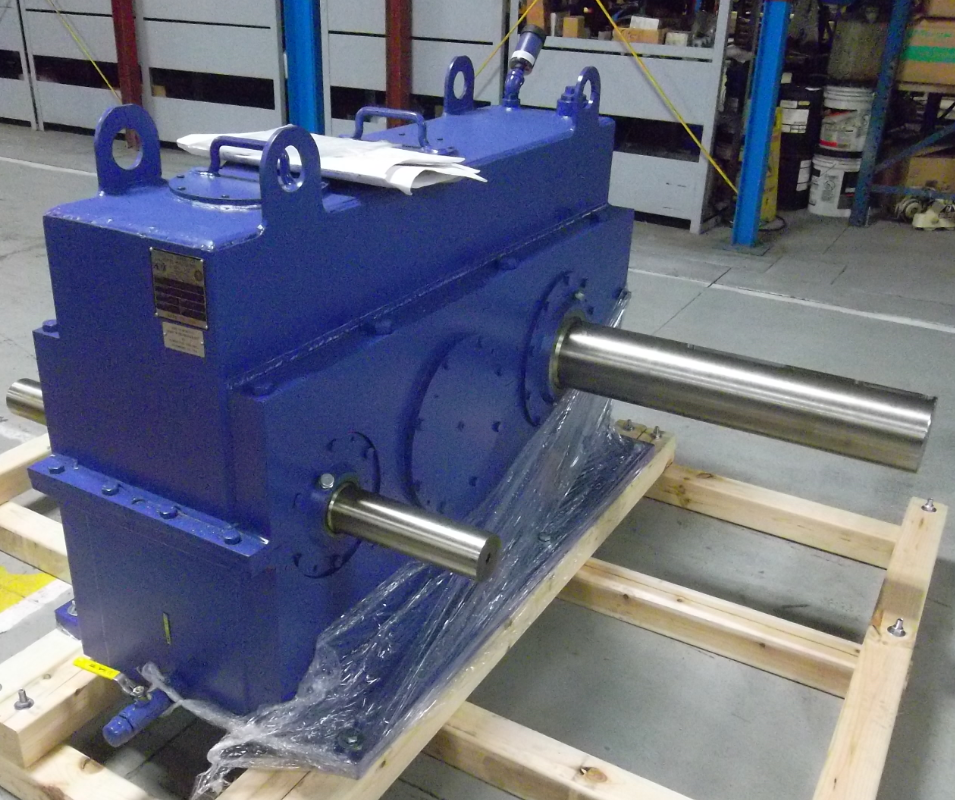

The primary gearbox is a horizontal parallel shaft double reduction reducer with helical gears. It has double extended input and output shafts. The reduction ratio of this gearbox is 17.684:1. It has two 75 HP electric motors, one on each side, turning the input shaft at 352 RPM. The output shaft turns at 19.9 RPM with a torque of 39,583 ft-lb. The output shaft turns the input shaft of the secondary gearbox on each side of it. Some of the challenging aspects of designing this gearbox were the space constraints as well as the required locations of the input and output shafts. These constraints were the driving factor for the split case design where the bearings bores are split through the middle.

The secondary gearboxes are single reduction reducers with double helical gears. Each one has a solid input shaft on one side and a hollow tube output shaft. The reduction ratio of this gearbox is 3.674:1. Since a secondary gearbox is on each side of each bridge half, they had to be designed such that they can be assembled in either a left-hand or right-hand orientation (mirror image). Each secondary gearbox had to be designed to handle 23,750 ft-lbf of torque at 19.9 RPM at the input shaft, which is equivalent to 90 HP. All 6 gearboxes were tested at 100% full load at PEM.

A special thanks to Hardesty & Hanover and SLSMC for entrusting us with this massive opportunity!